When you think of plumbing solder, electrical work probably isn’t the first thing that comes to mind. But hold on—before you dismiss this idea, consider this: plumbing solder is like the Swiss Army knife of the DIY world. It’s versatile, reliable, and can save you from that dreaded trip to the hardware store for yet another tool.

Imagine a world where your electrical connections are as solid as your plumbing joints. Using plumbing solder for electrical projects can provide a strong bond, making sure everything runs smoothly. Plus, you’ll impress your friends with your unconventional skills. So grab that solder and let’s dive into the unexpected benefits of this handy little tool. Who knew plumbing solder could be the unsung hero of your electrical endeavors?

Table of Contents

ToggleUnderstanding Plumbing Solder

Plumbing solder serves as a vital element in both plumbing and electrical applications. Its unique properties make it an effective choice for creating strong connections in various DIY projects.

What Is Plumbing Solder?

Plumbing solder consists of a metal alloy that melts at low temperatures. It typically combines tin and lead, although lead-free options are available for safety. This alloy allows for the joining of metal components securely. Plumbers commonly use solder to bond pipes and fittings. The process of soldering creates a reliable seal that resists leaks and ensures long-lasting connections.

Types of Plumbing Solder

Different types of plumbing solder exist to meet specific needs. Soft solder, generally made of tin and lead, works well for low-temperature applications. Lead-free solders, composed of tin mixed with copper or silver, provide a safer alternative for plumbing tasks. Another option includes silver solder, which offers high strength for demanding environments. Each type serves distinct purposes, ensuring optimal results based on project requirements. Selecting the appropriate plumbing solder contributes significantly to the success of the task at hand.

Applications of Plumbing Solder in Electrical Work

Plumbing solder plays a significant role in electrical applications, offering unique advantages for various projects. This versatile material provides reliable connections while maintaining ease of use.

Benefits of Using Plumbing Solder

Using plumbing solder in electrical work presents several benefits. It creates strong, lasting bonds between wires and components. The low melting point allows for quick, efficient soldering without damaging sensitive parts. Lead-free options ensure safety compliance in residential installations. Additionally, its cost-effectiveness makes plumbing solder an attractive choice for DIY projects, helping to reduce overall expenses.

Common Electrical Projects Utilizing Plumbing Solder

Various electrical projects commonly utilize plumbing solder. Wiring repairs often benefit from its reliable connections. Soldering circuit boards requires precision and stability, making plumbing solder suitable for such tasks. Hobbyists frequently use it in model building to connect electronic components. Furthermore, plumbing solder excels in low-voltage applications where reliability is critical, ensuring a secure and functional setup.

Safety Considerations

Using plumbing solder in electrical applications requires attention to safety. Understanding the potential risks and maintaining proper handling ensures successful and safe projects.

Health Risks and Precautions

Health risks associated with plumbing solder include exposure to lead and toxic fumes. Lead exposure can occur through inhalation or skin contact, posing serious health concerns. It’s important to work in well-ventilated areas to minimize fume inhalation. Wearing personal protective equipment such as gloves, goggles, and masks reduces the risk of contact. Opting for lead-free solder addresses health concerns, making it a safer choice for electrical work. Familiarity with safety data sheets enhances awareness of risks related to specific solder types. Keeping children and pets away from work areas prevents accidental exposure.

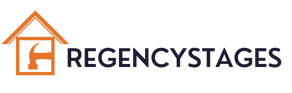

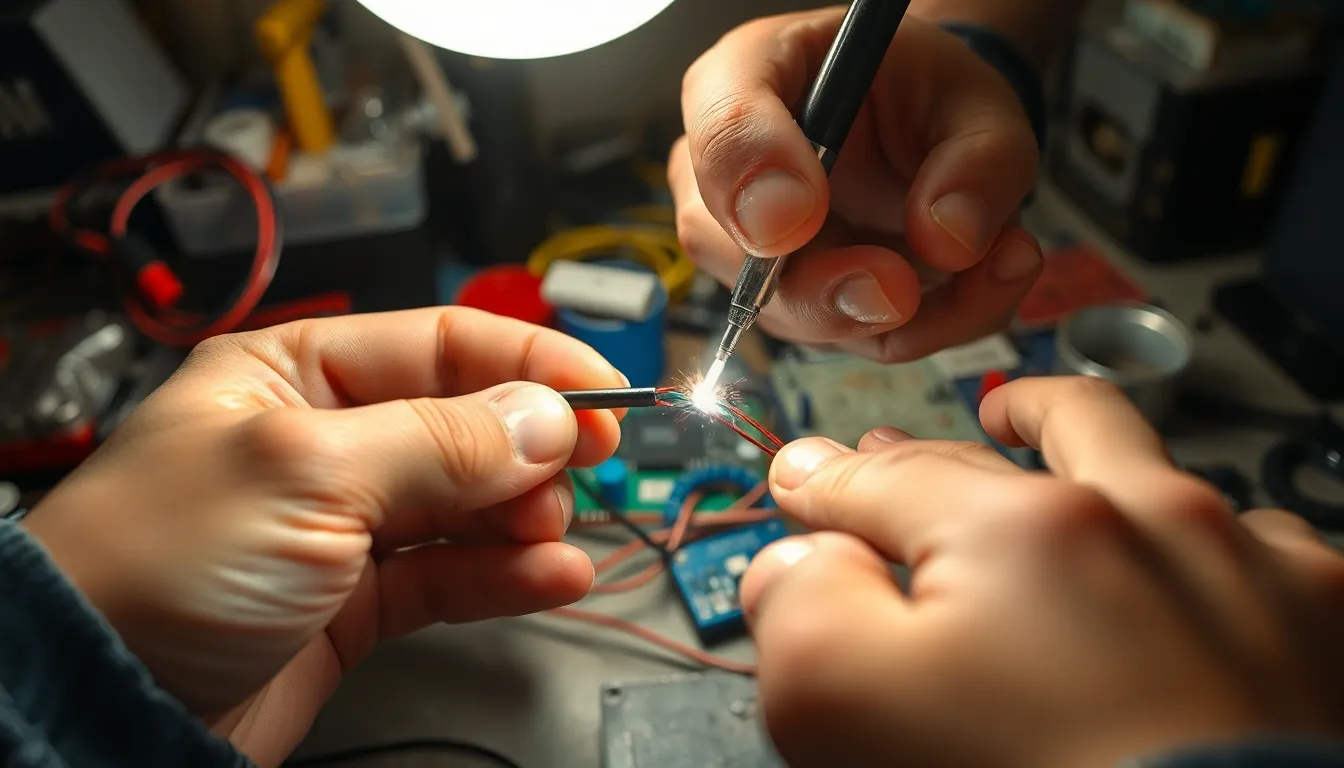

Proper Handling and Application Techniques

Proper handling techniques enhance safety and effectiveness during soldering. Always use a soldering iron at the recommended temperature to prevent overheating, which may produce dangerous fumes. Maintain a clean workspace, as debris can lead to accidents or contamination. Secure connections and use clamping tools to stabilize components before soldering. Applying solder effectively involves heating both the workpieces and the solder simultaneously. This promotes better adhesion and reduces the risk of damaging sensitive parts. Cleaning electrical surfaces beforehand ensures optimal bonding and improves the overall quality of completed connections.

Alternatives to Plumbing Solder for Electrical Use

Copper solder presents a strong alternative for electrical applications. Different from plumbing solder, it ensures effective conductivity. Various types are available, including 60/40 tin-lead mixtures which melt at lower temperatures.

Lead-free solder offers another option for safety-conscious projects. Composed primarily of tin with elements like copper or silver, this type adheres to health regulations while maintaining reliable connections. High-temperature applications often benefit from silver solder due to its superior strength and thermal resistance.

Electrical solder specifically designed for electronic projects is widely available. This formulation frequently contains rosin core, enabling efficient soldering without needing a separate flux. Enhanced wetting properties contribute to strong bonds, ideal for circuit boards and delicate components.

Soldering wire represents a straightforward alternative. Dissimilar from plumbing solder, these wires provide flexibility during installation. With various thicknesses available, it’s easier to match the project requirements.

Solder paste serves as a suitable replacement for some electrical jobs. Typically utilized in surface-mount technology, this paste combines solder and flux, allowing for precise application on circuit boards. Its ability to flow into small spaces ensures reliable connections in compact layouts.

Consider connecting terminals or using crimp connectors for electrical tasks. They offer a quick and effective way to join wires without heat. Options like heat-shrink tubing can enhance durability and insulation, making them ideal for various projects.

Evaluating compatibility is essential when opting for alternatives. Each type has unique properties, causing variations in conductivity, bonding strength, and melting points. A careful selection guarantees the success of electrical tasks while prioritizing safety.